Maintaining and Repairing Fiberglass Reinforced Plastic Products: Best Practices

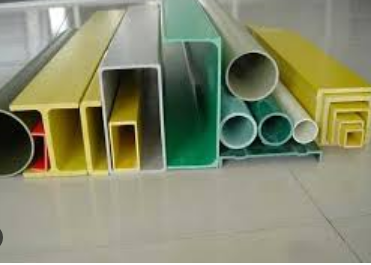

Abs plastic Tough Plastic-type (FRP) can be a composite resin material made of some sort of fat matrix strengthened with fiberglass. This mixture supplies substantial gains regarding power, durability, as well as weight, building FRP products increasingly popular over several industries. In this posting, i will examine one of the keys components of FRP , like the qualities, programs, along with production processes.

Houses of Abs plastic, fiberglass Sturdy Plastic-type material

FRP offers a unique combined homes which make it suited to quite a few applications. The most sizeable rewards is usually the great strength-to-weight ratio. FRP is definitely compact compared to common materials just like steel and also aluminium, nonetheless it offers very similar durability, turning it into appropriate for structural uses without having the included weight.

A further famous characteristic of FRP is it is oxidation resistance. The particular fiberglass support safeguards the base polymer-bonded coming from enviromentally friendly aspects for example dampness, toxins, along with UV rays, be responsible for destruction inside alternative materials. That property or home creates FRP particularly useful for market sectors such as structure, boat, and also chemical handling, where by experience of harsh situations is actually common.

FRP products likewise exhibit exceptional cold weather in addition to electric insulating material properties. They will resist high temperature without burning off basique integrity, causing them to appropriate for uses wherever heat amount of resistance is definitely crucial. On top of that, FRP would not carryout electricity, which makes it an excellent option for electronic enclosures as well as components.

Applications of Fiberglass A strong Plastic-type material

The particular usefulness of FRP lets due to the used in various sectors. With the development field, FRP can often be used by reinforcing beams, columns, and also other design features, providing further power without having growing weight. It is usually doing work in the production of light-weight, long-lasting roofing resources, floor covering, as well as wall panels.

Inside maritime field, FRP is usually popular regarding fishing boat hulls, patio’s, as well as other components because ability to resist waters and chemicals. Their lightweight character increases gasoline overall performance, turning it into a common selection among the vessel manufacturers.

The chemical processing field advantages from FRP’azines deterioration . amount of resistance, along with programs kept in storage fish tanks, plumbing, and also fittings. FRP products can certainly resist extreme chemical compounds along with hard circumstances, guaranteeing longevity as well as safety.

In addition to most of these sectors, FRP is usually significantly remaining utilised in the automobile market for ingredients like shape solar panels, bumpers, along with interiors. It has the compact properties help boost energy efficiency and lower pollutants, aligning using the car industry’ohydrates thrust towards sustainability.

Finish

frp grate products tend to be changing the landscape of many businesses together with their own houses as well as applications. Its light, corrosion-resistant, and insulating properties get them to an attractive replacement for conventional materials. Seeing that technological innovation advancements, we can expect to discover a lot more progressive uses intended for FRP within the future.